No Events

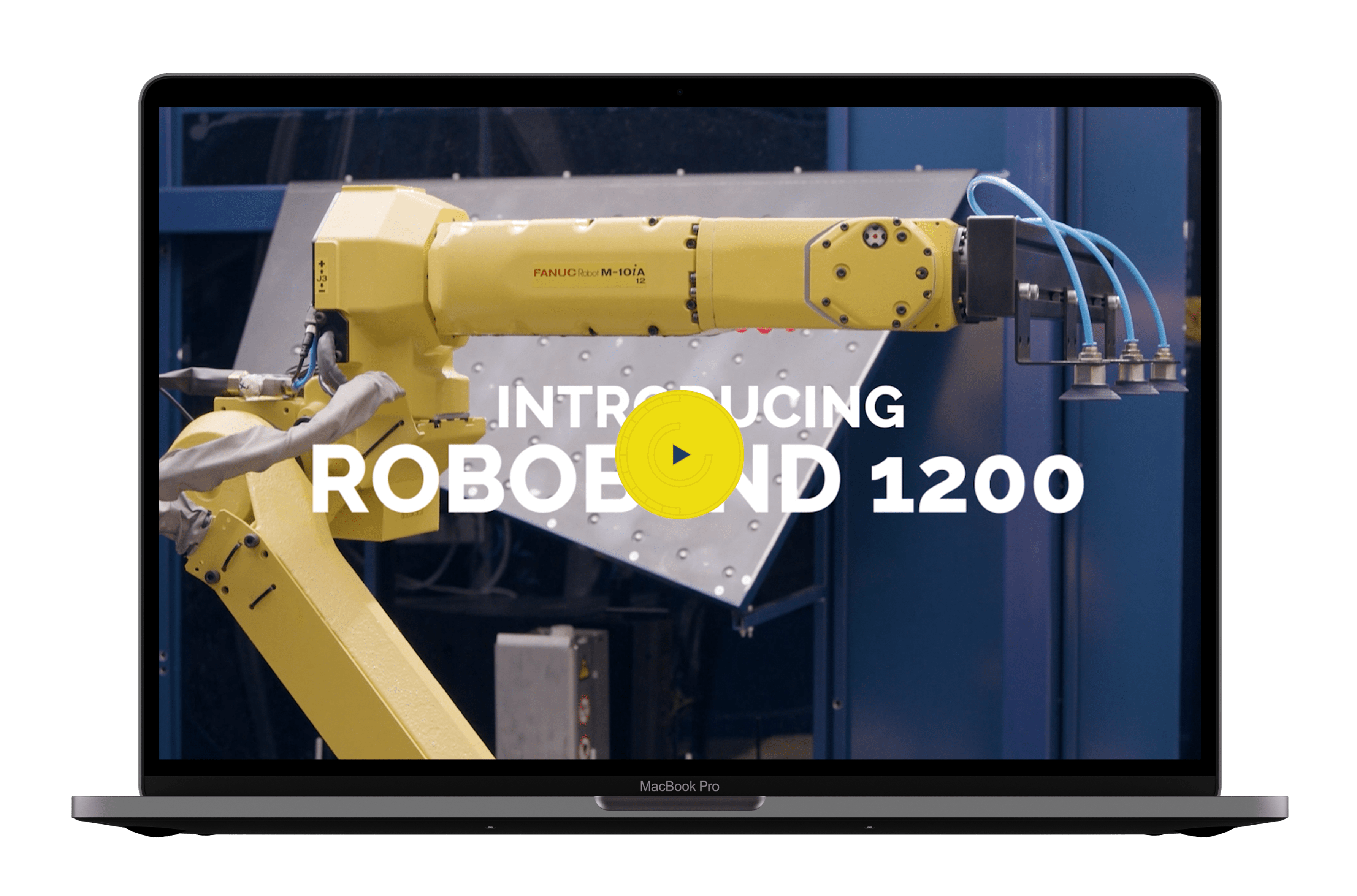

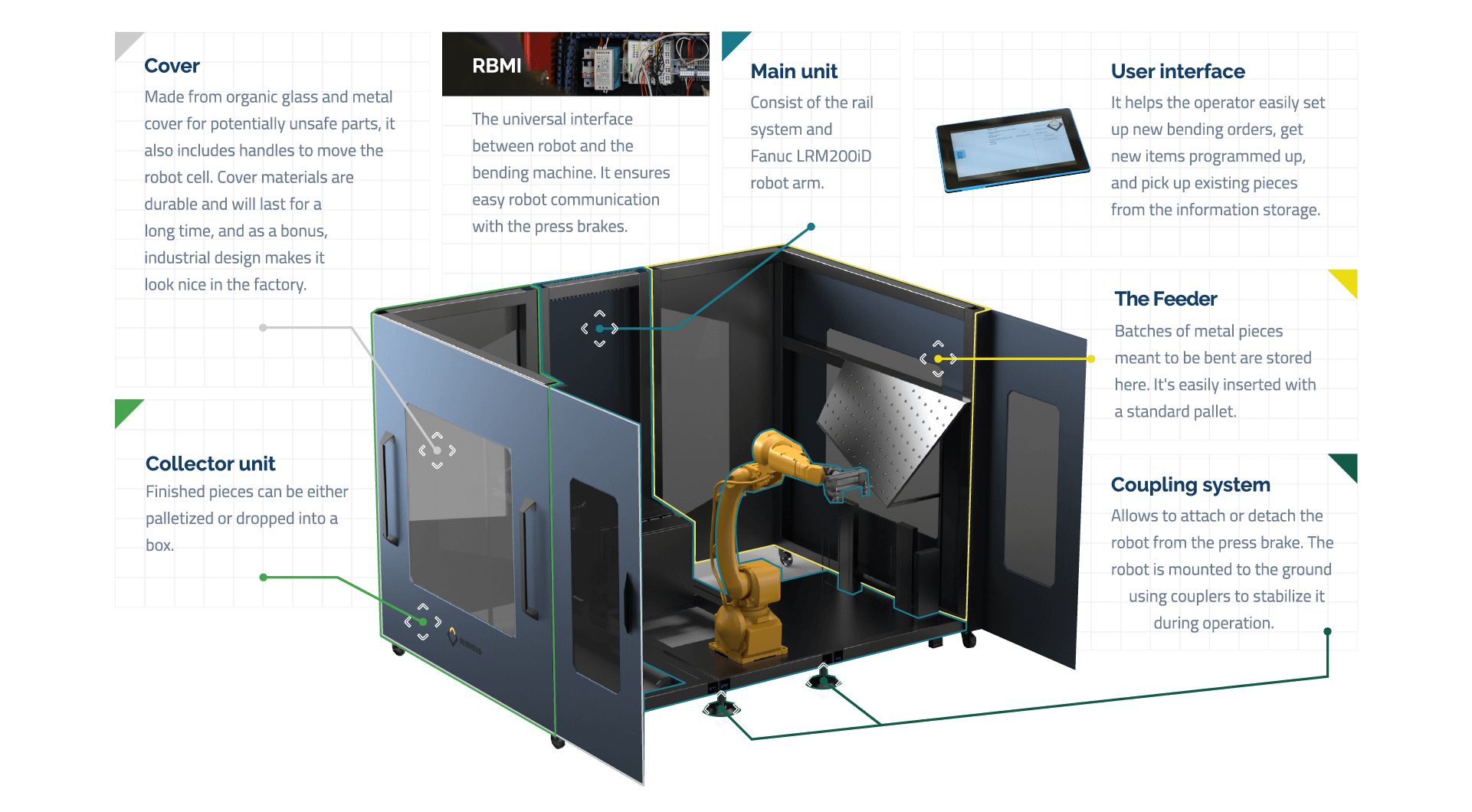

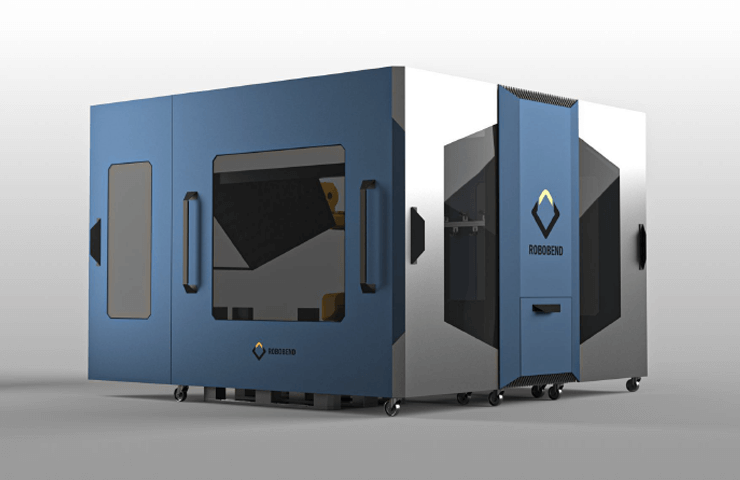

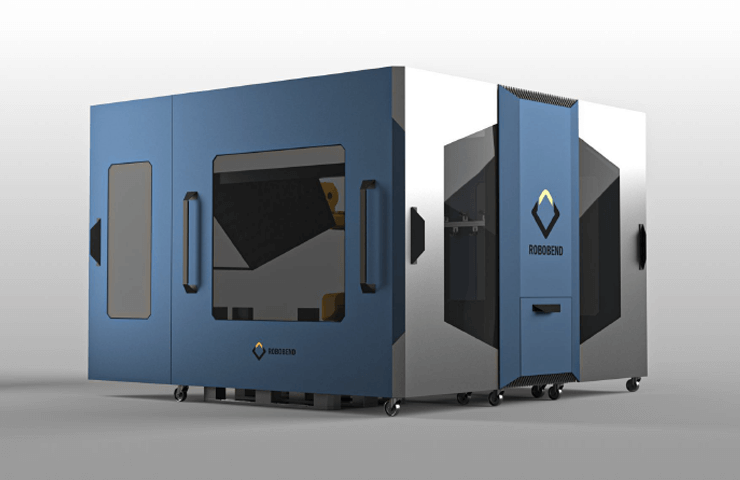

RoboBend is a mobile robot cell for sheet metal bending.

It’s compatible with any existing press brakes on the market and has easy-to-use software that ensures high capacity and high quality bending even for smaller batch orders.

Made to deliver short pay-back time for small and medium-sized enterprises (SMEs)

High precision and accuracy delivers the same high quality every time.

© 2021 RoboBend · Privacy Policy · Terms of Use

Robobend is part of a sub-project that has indirectly received funding from the European Union H2020 research and innovation program via an Open Call issued and executed under project TRINITY (grant agreement No 825196)

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |